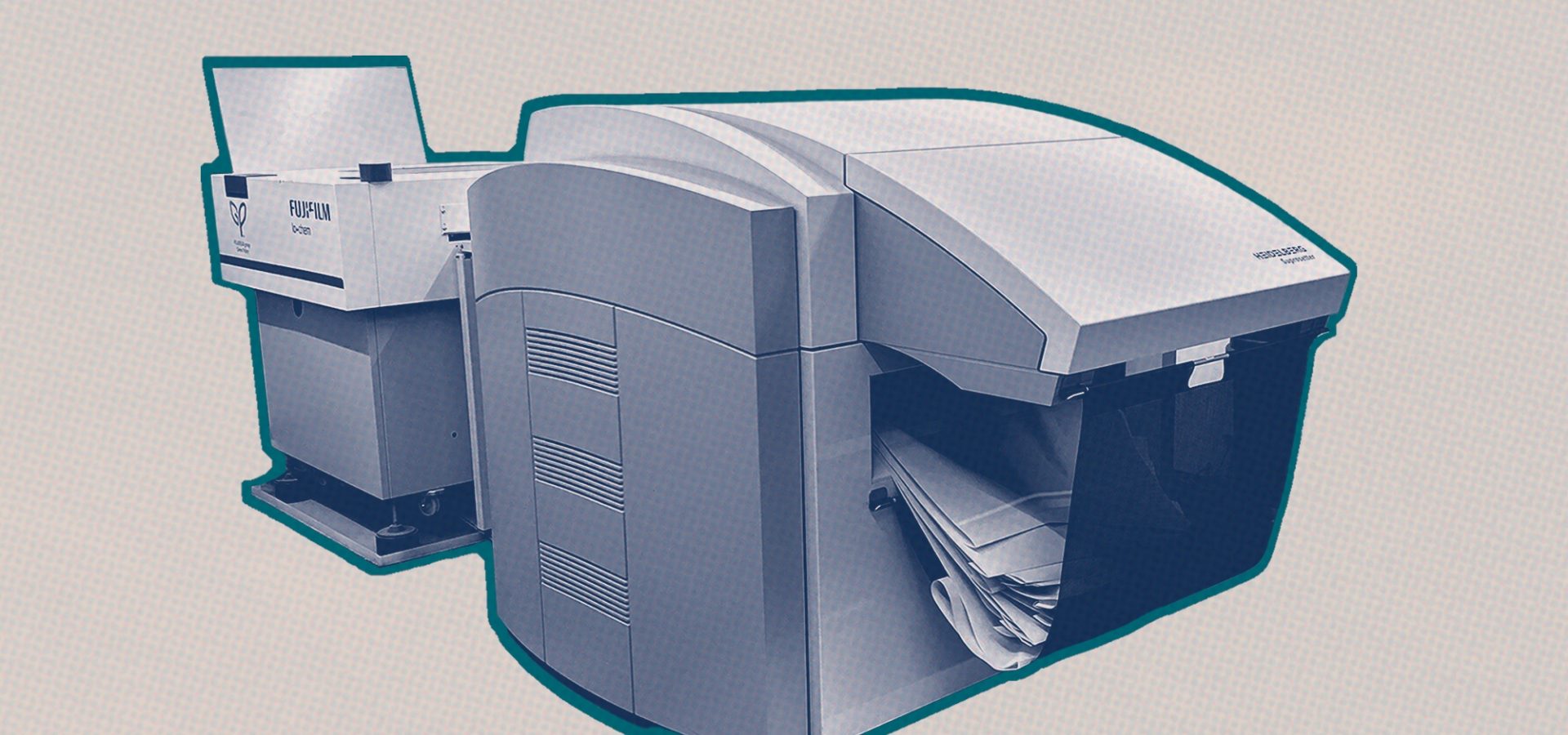

At the core of print manufacturing, printing plates are an essential part of the printing process. These plates, crafted from aluminium, are prepared with images, text, or graphics through our Heidelberg A75 Suprasetter which lasers the graphics onto the plate. The printing plate is then put through a processor where chemicals and water are used to remove any nonessential coating used to create the imagery on the plate.

Our previous system, the Fujifilm 'lo-chem' range, was a progressive choice at the time, designed to use minimal chemicals. Despite its reduced chemical reliance, we recognised the need for a more sustainable approach.